Tri-Layer Acrylic Engraving: Why Most Engravers Won't Touch It & Why You Should Care

Tri-layer acrylic engraving represents one of the most technically demanding processes in the laser engraving industry. While the results are stunning and highly professional, the complexity involved means most engravers simply won't take on these projects. Here's why this specialized service is so challenging—and why it's worth finding an expert who can deliver.

What is Tri-Layer Acrylic?

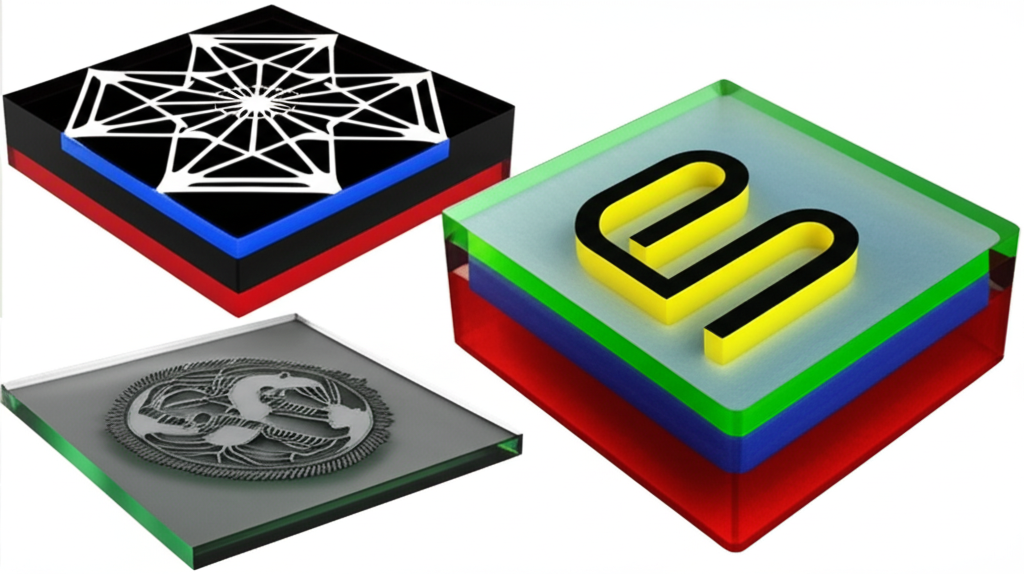

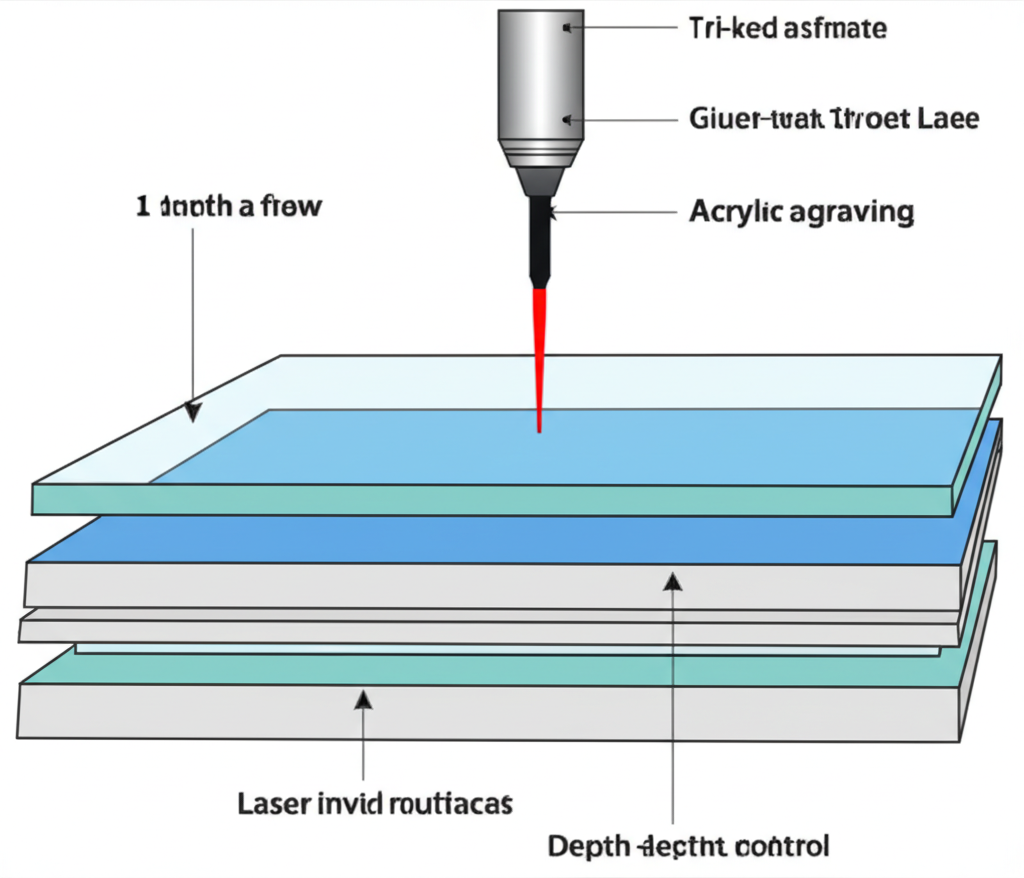

Tri-layer acrylic consists of three distinct layers: a colored top layer, a contrasting middle core, and a protective backing. When laser engraved, the top layer is precisely removed to reveal the contrasting color beneath, creating crisp, professional-looking text and graphics.

This material is ideal for applications requiring high contrast, durability, and a premium appearance— making it perfect for business signage, equipment labels, hat patches, awards, and decorative elements.

Why Most Engravers Won't Touch Tri-Layer Acrylic

Precise Power Control Required

The laser must remove exactly the right amount of material—too little and the engraving is incomplete, too much and you burn through to the backing layer, ruining the piece.

Speed & Frequency Mastery

Each color combination requires different settings. What works for white-on-black won't work for red-on-white, requiring extensive testing and expertise.

Material Inconsistencies

Different manufacturers and even different batches can behave differently under laser engraving, requiring constant adjustment and testing.

High Waste Potential

Mistakes are costly—tri-layer acrylic is expensive, and ruined pieces can't be salvaged, making many engravers hesitant to take on these projects.

Popular Applications for Tri-Layer Acrylic

Business Signage

Professional door signs, office nameplates, and directional signage with crisp, high-contrast text.

Awards & Recognition

Employee recognition plaques, achievement awards, and commemorative pieces with professional appearance.

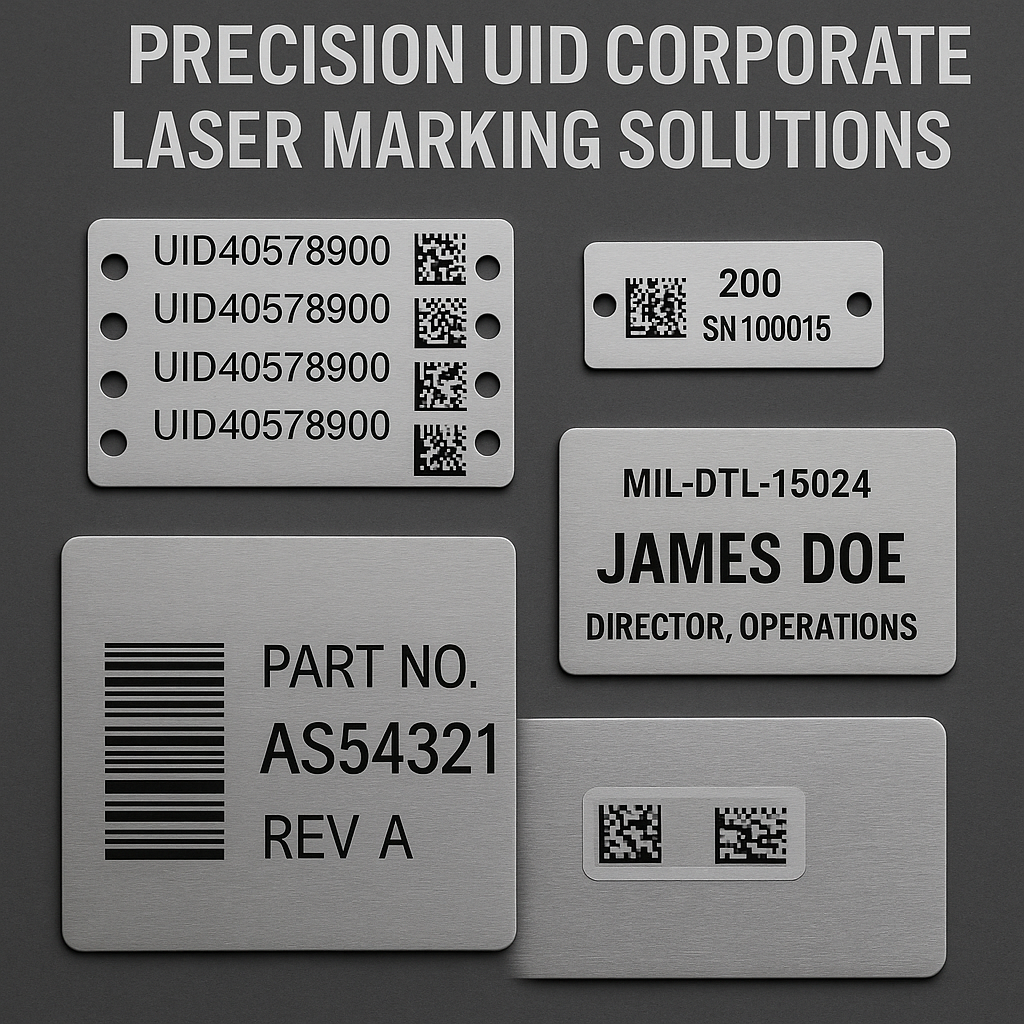

Industrial Labels

Equipment tags, safety labels, and control panel markers that need to withstand harsh environments.

Other Popular Uses:

- Hat patches and uniform accessories

- Control panel labels and buttons

- Decorative architectural elements

- Memorial and commemorative plaques

- Trade show displays and booth signage

- Custom promotional items

Why Tri-Layer Acrylic is Worth the Investment

Exceptional Durability

Unlike printed signs that fade or peel, tri-layer acrylic engraving is permanent. The contrasting color is integral to the material, not applied on top, ensuring longevity even in harsh conditions.

Superior Contrast

The high contrast between layers creates exceptional readability, making it ideal for safety signage, equipment labels, and any application where visibility is critical.

Professional Appearance

The clean, crisp edges and consistent depth create a premium look that elevates your brand image and communicates quality and attention to detail.

Versatile Applications

From indoor office signage to outdoor industrial labels, tri-layer acrylic performs consistently across a wide range of environments and applications.

Finding the Right Tri-Layer Acrylic Specialist

What to Look For:

Experience & Portfolio

Ask to see examples of their tri-layer work. Quality specialists will have a portfolio showcasing various color combinations and applications.

Material Knowledge

They should understand different manufacturers, color combinations, and be able to recommend the best material for your specific application.

Testing Process

Professional shops will test settings on sample pieces before running your job, ensuring perfect results without waste.

Quality Guarantee

Reputable specialists stand behind their work and will remake pieces that don't meet their quality standards.

Ready for Professional Tri-Layer Acrylic Engraving?

At EZ Engrave Everything, we've mastered the art and science of tri-layer acrylic engraving. With years of experience and specialized equipment, we deliver the precision and quality your business deserves—every time.